Which learning technologies should you invest in when it comes to training employees in production companies? uQualio has been part of a MADE – Manufacturing Academy Denmark experiment in the Learning Factory project at VIA University College.

Dive into the fresh results and learn what the technologies can (and cannot) be used for , along with their their pros and cons.

(This is a translation of a Danish article made by MADE – the original can be found here: https://www.made.dk/artikler/hvilke-laeringsteknologier-fungerer-til-hvad/)

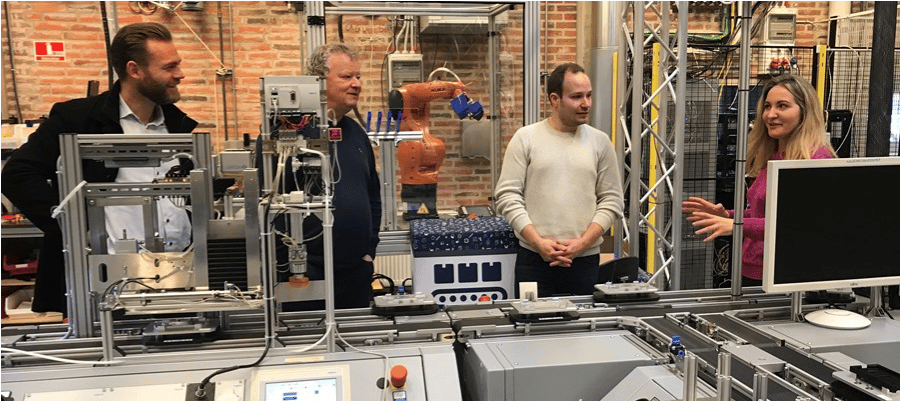

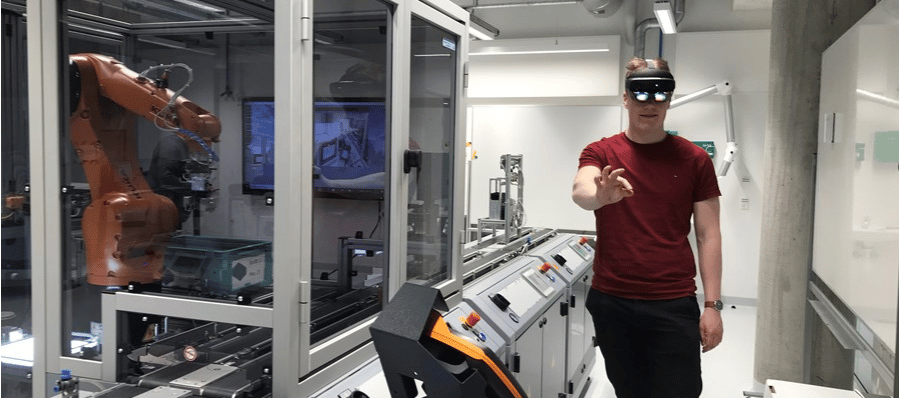

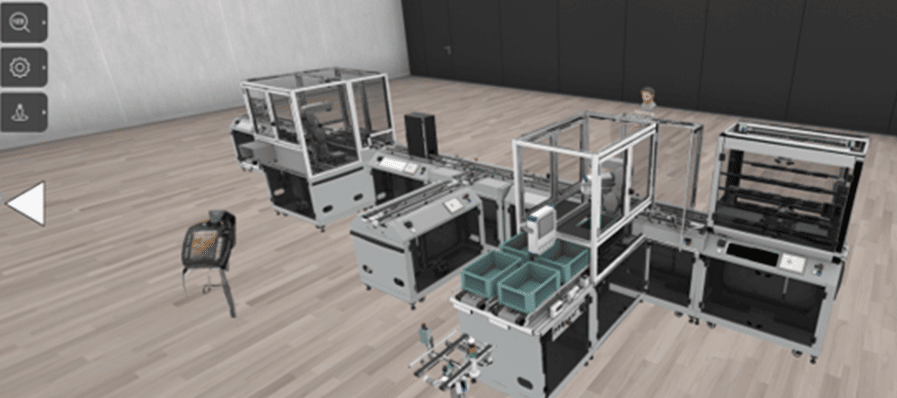

The Virtual Reality (VR) glasses slide down over the eyes and a virtual arrow appears in the right corner of the field of view. Through virtual instructions, the glasses guide the wearer to turn and press buttons until the Festo model factory in front of him is brought to life – ready to simulate a very realistic production of mobile phones.

At the same time, a number of workshop participants from companies in the local area sit and curiously follow the session at VIA University College’s learning laboratory.

“It was nice to see that it worked in practice,” says course participant Oksana Christensen, a project manager at VELUX.

A Technology Knowledge Gap

Precisely what works – and what doesn’t, is in focus at today’s workshop, which is the culmination of a MADE Learning Factory project, where VIA and MADE have tested a number of digital learning technologies.

“Many SMEs are lagging behind in development, also because they are unsure of the benefit the technologies can give them, and they also lack knowledge of the technologies,”, says assistant professor at VIA Jonas Emil Rex Justesen, who has participated in the design of the learning factory.

Overview of Uncharted Territory

The tests took place at VIA, where different groups of students had a manual stuck in their hands (or on their heads) to start up the Festo system.

“We had experienced that some of our students had difficulty starting up our FESTO system, so there was a possible case,” elaborates associate professor at VIA Flemming Korf Davidsen, who also participated in the project and is interviewed in the company of colleague Jonas Emil Rex Justesen.

For each test, a group of students was given a new type of manual: paper, VR, HoloLens, RealWear, or video training.

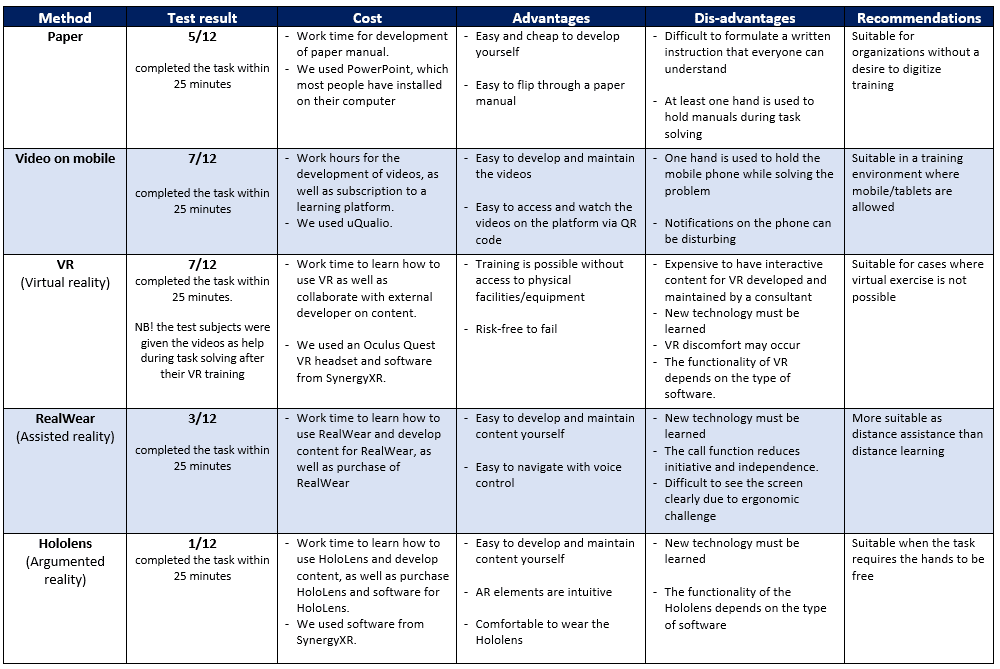

The matrix below summarized the results from the tests with advantages, disadvantages, and recommendations.

Back at the workshop with the local companies, the matrix is presented and held up against own experiences.

“It’s an area where there’s really, really much going on,” says Oksana Christensen, adding: “Digital training can increase the quality of the training and make it more efficient, but we have many considerations about which technology is suitable for which task. Here, the matrix will be able to help make our selection process shorter.”

Get a look into the process, where students tested the new technologies at VIA, with the chief consultant at MADE Camilla Nellemann. She has been responsible for analyzing data from the tests. https://www.youtube.com/embed/V17PklyDLCM?feature=oembed (In Danish)

Get a look into the process where students tested the new technologies at VIA, with the chief consultant at MADE Camilla Nellemann. She has been responsible for analyzing data from the tests.

For Many, New Learning Technology Is Difficult…Quite So Difficult

Chief consultant in MADE Camilla Nellemann is responsible for the MADE Learning Factory. At VIA, she observed the tests and analyzed data. According to her, the students were ‘enthusiastic guinea pigs’, but:

“There was a huge difference in how easily they used the technologies,” she says and continues: “The digital inequality, which studies show is large in the population, really came to the fore.” In fact, the difficulty of figuring out how to use the technology meant that some never really got started with what the technology was actually supposed to help them with – namely starting the Festo plant.

“The more technological a solution we tested, the worse the results,” explains Camilla Nellemann.

This was shown, among other things, when 12 students tried to start up the Festo factory with a HoloLens manual. Here, just one completed the task within the time frame of 25 minutes – and then even in just 16 minutes.

“He passed compared to the others, despite the fact that everyone had received a 10-minute instruction. It clearly shows the digital inequality and that an investment in XR learning technology is also an investment in training to use the technology,” explains Camilla Nellemann.

The Learning of the Future Rhymes with Advanced Technology

When it came to VR technology, there was also a big difference in how easily the test subjects had to navigate in VR. According to Camilla Nellemann, this is because some have tried the technology before in games. Plus, it also answers why the more advanced technologies are “absolutely a good idea” despite poorer results:

“The XR technologies had the most potential to best solve the task. They are just not something people are used to yet. But, we will be, as it will become part of our education and our everyday life. In the 00s, event the best eLearning platforms were also presented with long manuals. However, today we don’t need a manual at all. This is because we are used to navigating online,” explains Camilla Nellemann. “In the research project, most test subjects completed the task using the video manual.”

Another discovery made through the tests was that RealWear, where it is possible to call an expert for help, was clearly more suitable for remote assistance than distance learning. This is because the feature was ‘overused.’

“It was a surprise to learn how the call function tended to remove initiative and independence from the test subjects.”

The Next Generation Is Ready

The experiments in the learning laboratory at VIA have boosted the transformation toward digital learning at the school.

“The project has given us the opportunity to test and use some technologies that we don’t normally use,” says Associate Professor at VIA Flemming Korf Davidsen and adds:

“They have to go out to live on the further education, and we would like to use it in more education for our students.”

And that, according to Jonas Emil Rexen Justensen, is a really good thing. This is also because the market is screaming for people who have digital learning technologies under their fingernails:

“Students who have a handle on these digital technologies manage to fly. These are skills that are in demand – also because they are simply not there today at SMEs.”

Another advantage is that the team at VIA has messed with the technologies themselves. As a result, they have understood how companies can use them. This way, VIA can provide much better advice in this area.

“Now we understand, for example, how long it takes to develop a digital twin, because we have sat with it ourselves,” explains Jonas Emil Rexen Justensen.

Good Advice for Choosing Learning Technologies

Precisely drawing on the experiences of others is also the advice that colleagues from VIA emphasize when it comes to considerations for digital training:

“Use some sparring partners – for example, us or MADE. We have learned the irrelevant things so that others don’t have to do it,” says Flemming Korf Davidsen, while Jonas Emil Rex Justesen nods affirmatively.

“It is good to have sparring to avoid wrong investments. We have had many good experiences based on concrete learning situations. For example, a static 360-degree camera can deliver some specific recordings and experiences. But, a mobile camera can be more useful in other situations. Reason being, most of us today have a mobile,” he adds.

According to Camilla, besides sparring, there are two important learnings from the project to consider before embarking on new digital learning adventures.

“It is incredibly important to take digital inequality into account. One should also ensure that everyone has a successful experience with the technology the first time. Plus, it is critical to develop one’s manual through an iterative process. This will allow you to test it on the target group and adjust it several times.”

MADE Learning Factory

MADE Learning Factory is part of the research platform MADE FAST, which, among other things, works towards creating a sustainable and agile workforce.

In the MADE Learning Factory, we develop flexible learning courses for engineers, technicians, and production employees.

The effort is based on The University of Applied Sciences UCN in Aalborg (UCN), VIA University College in Horsens (VIA), and Copenhagen Business Academy in Copenhagen (KEA).

Contact Camilla Nellemann at cnellemann@made.dk if you want to learn more.

Achieve Effective & Affordable Video Training

– uQualio is an award-winning, easy-to-use, all-in-one NextGen LMS software for any types of online video training.